How to Get Started with 3D Printing

The tech media is abuzz with news of the latest developments in 3D printing. What seemed to be the reserve of a select few, is now increasingly being adopted by the mainstream with impacts on a many corners of society. From prototyping for engineering projects to creative hobbyists at home – 3D printing is one in a string of modern day tech revolutions.

So you’ve decided to take the leap and join the world of 3D printing, but what next? With choice abound, every stage of the journey can be fraught with indecision and challenges. Which 3D printer is best for you? How does 3D modeling software work? What make a good three-dimensional model? Here are just a few tips to help you navigate this very current technical minefield:

Choosing the Right 3D Printer for You

First of all, what kind of 3D modeler do you plan on being? Entry level printers for hobbyists, designers and small businesses are a great place to start for beginners wanting to test the water. There is a wide range of models to choose from and burgeoning community of fellow enthusiasts only a Google search away from resolving your additive manufacture woes. While prices vary, 3D printers in this category range from around £500 – £2000.

These printers come in a number of guises from “plug and play” to self-build kits. The key here is to do your research, are you looking for a tool to help you follow your dreams of becoming a prototyping magnate or are you more interested in tinkering with an ongoing project in your shed? Only you can answer this question; either way there’s a printer out there for you.

What to Print? Planning is Key

With recent news of printed jet engines, clothing and motorcycles, the options are endless. As with any good project, fail to prepare and prepare to fail – planning is key!

Your first step should be to grab a pencil and get sketching. Once you’ve sufficiently developed your idea, it’s time to move on to modelling. Your 3D object needs to be designed on a computer. Software such as Autodesk will help create digital version of your design that’s ready to print. Once the design in complete, you’re ready to go!

Printing

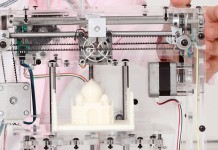

Now, for the exciting part. You’ve done all the groundwork and your design is about to realised. There are numerous kinds of 3D printer they work in many different ways. Printers such as the idbox from ModelSpace work using fused deposition modelling. This process involves molten additive being extruded and layers in strips, building your model from the bottom up. As the material cools in the air, it hardens rapidly and forms and solid structure. Once the process is complete, your model is almost ready to go.

Don’t forget the Detailing

Add a professional finish to your work. With the structure of your model complete, now’s your chance to add the finishing touches to make your work stand-out. Once, cooled your model is ready to be smoothed and painted until you’re satisfied with the result. Grooves and blemishes can be ironed out using a file or sandpaper and acrylic paints are perfect for giving your project the final touches.

Armed with your printer and your imagination, you’re ready to get creative. The web is full of inspiration and there’s a growing community of 3D printing fans out there to help.

Fancy building your own 3D printer? Check out our blog on the idbox – our very own, much loved partwork, click here

Whatever you create, we’d love to hear how it goes – feel free to comment below.